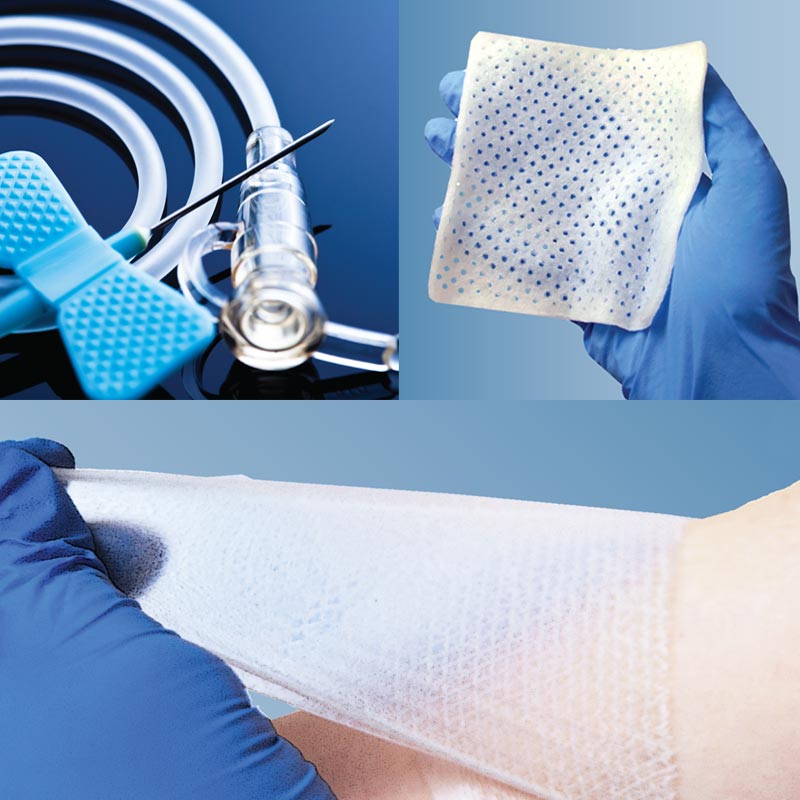

Customized Medical Device Coatings

Solve new challenges around infection prevention, tissue repair and patient comfort with our coating, silicone and biomatrix technologies.

Our patented approach is supported by an FDA device master file and creates a highly durable, low particulate coating technology through surface modification, designed to withstand shear forces and delamination to improve the performance of medical devices. CovaCoat® coatings can be applied to a number of medical devices, including:

- silicone and latex catheters,

- peritoneal dialysis catheters,

- hemodialysis catheters,

- wound drains,

- central venous lines,

- orthopedic metals, and

- several other medical devices

Benefits

Customizable

Highly tunable

Durable

Multifunctional

Controlled delivery

Cost Effective

Compared to other coatings which rely on “grafting to” processes with off-the-shelf polymers, our coatings uses a proprietary “grafting from” process to prevent weak points and potential delamination. Utilizing photo-polymerization to create active grafting sites, new polymer chains are initiated and grown from the surface to form a continuum rather than a discrete coating layer.

The CovaCoat® process works best with polymer-based materials but can be applied to virtually any medical device or other surface material. Using USP grade material and an ISO compliant quality system, the CovaCoat® process has been scaled for commercial production of many FDA, Health Canada, CFDA approved products.

Dual Antimicrobial Silicone Adhesive Technology

Benefits

Collagen Matrix Technology

Covalon develops sophisticated and “pro-active” collagen technologies that create a catalyst for accelerated tissue healing, superior infection control and improved patient outcomes. Our collagen technology can be customized to create unique advanced wound care, trauma and surgical repair products.

The unique mechanisms of action in ColActive® biomatrix is a result of Covalon’s patented manufacturing process that produces a crosslinked matrix of collagen containing both native-like triple helical and denatured random coil configurations of collagen chains. The partial unwinding of the collagen triple helix in our dressings expose a greater proportion of the polypeptide sequence to potential interactions with wound site components, improving healing capacity.

We have worked with a number of medical device suppliers to contract manufacture OEM Collagen Matrix solutions that meet their needs.

Benefits